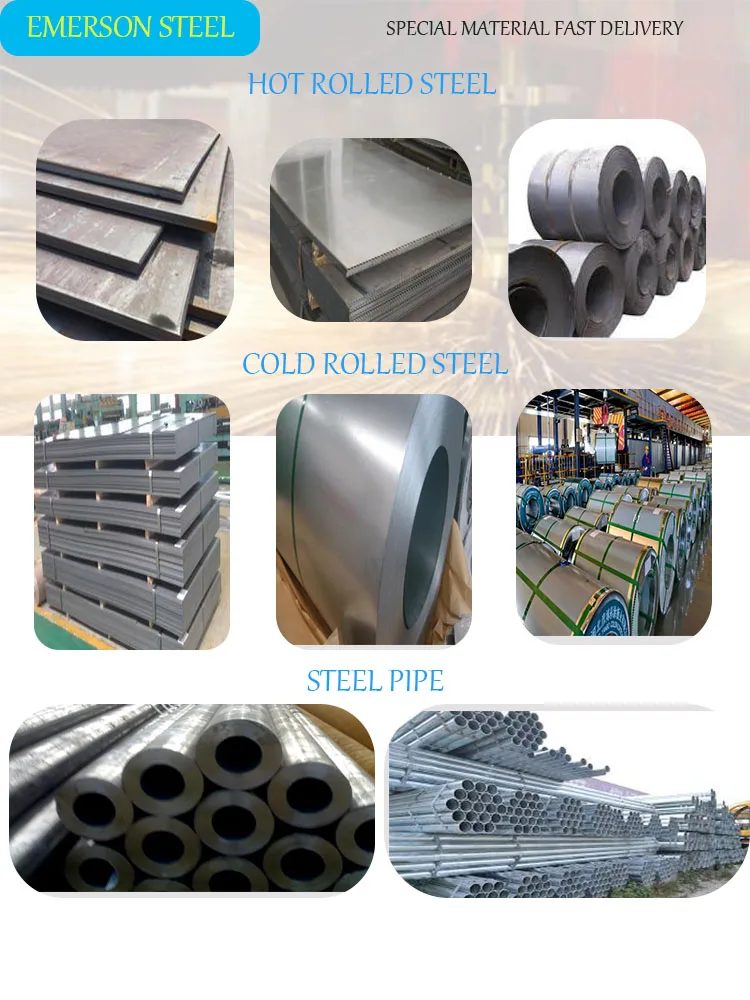

304 stainless steel sheet has good resistance to many chemical corrosives and to industrial atmospheres and marine environments. Stainless steel sheets and plates also offer excellent load-bearing properties, high corrosion resistance, excellent durability, high strength to weight ratio, good thermal and electrical conductivity, ease of fabrication, ease of cleaning and high finish. 304 sheet is cost-effective and the most popular and economical of the stainless steels and is versatile for most applications where durable support and corrosion resistance are required. Both have their benefits depending on the application, and knowing these differences can help you decide which one will work best for your particular needs.304 stainless steel sheet and the plate featureįlexible 304 stainless steel sheet and the plate is ideal due to its high tensile strength, ease of roll forming or bending, rust resistance and machining capabilities. Knowing the differences between sheet steel and stainless steel can help you make informed decisions when selecting materials for your projects or products. Stainless steel is easy to clean and does not require special cleaners or treatments. Sheet steel requires more maintenance than stainless steel. Stainless steel is more expensive because of the addition of chromium and other alloying elements. Sheet steel is less expensive than stainless steel. Stainless steel is used in food processing, chemical processing, and medical equipment. Sheet steel is used in a variety of applications, including construction, automotive, and appliances. Stainless steel can withstand high temperatures and corrosive environments without being damaged. Sheet steel is less strong and durable than stainless steel. Stainless steel is made of chromium and other alloying elements that are added to low-carbon steel. Sheet steel is made of low-carbon steel that is rolled into thin sheets. The grade you choose will depend on your specific application needs. Low carbon grades are typically used in applications where corrosion resistance is important, while higher carbon grades are typically used in applications where strength is more important than corrosion resistance. Stainless steels are available in several grades that range from low carbon (304) to high carbon (440C). Unlike sheet steel, stainless steel does not need to be cold-rolled or hot-rolled instead, it can be formed into different shapes using pressure tools such as hydraulic presses or hammer mills. It’s also known for its strength, durability and resistance to heat, making it ideal for use in high-temperature applications such as cookware or automotive components. Stainless steel contains at least 10% chromium which makes it more resistant to corrosion than sheet steel.

Sheet steel can be cold-rolled or hot-rolled, depending on the application. It’s known for its strength and durability, as well as its ability to be moulded into different shapes or forms. Sheet steel is an alloy made up mainly of iron but also contained small amounts of carbon, manganese, sulfur, phosphorus and silicon. One of the main differences between sheet steel vs stainless steel is their properties. Difference Between Sheet Steel and Stainless Steel Properties In this post, we’ll explore the differences between sheet steel vs stainless steel and how they can be used in various applications.

Stainless steel is a type of steel that contains at least 10% chromium and is more resistant to corrosion than regular steel. Steel has many applications in construction, manufacturing, engineering, and other industries. Steel is a metal alloy made up of iron and other elements, the most common being carbon.

0 kommentar(er)

0 kommentar(er)